MARLBOROUGH, MASSACHUSETTS, USA — October 24, 2019 — Xtalic, a leader in providing nano-scale metal alloys and coatings that solve customers’ mission-critical materials problems, has announced that its new nanocrystalline Nickel-Chrome (Ni-Cr) alloys are engineered to reduce oxidation-based corrosion at temperatures up to 900°C — delivering a significant advantage to supplant the use of commercial Nickel (Ni) in many applications.

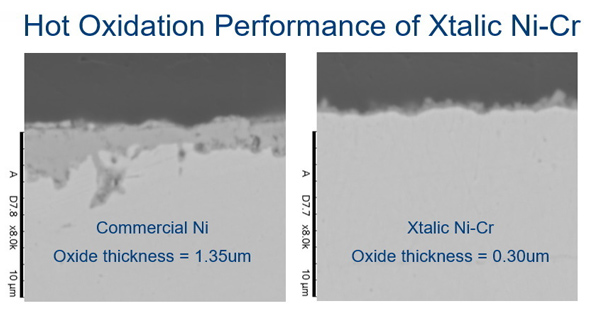

Comparing commercial Ni to our new nanocrystalline Ni-Cr alloy for hot oxidation performance at 700°C for 20 hours, the commercial Ni oxidizes quickly to create a thick oxide layer of 1.35um. In contrast, in the Xtalic nanocrystalline Ni-Cr alloy, the Cr selectively oxidizes at the surface to produce a thinner (0.30um) and protective chromium oxide layer on the surface.

In a wide variety of applications, new Xtalic Ni-Cr alloys are well suited to replace commercial Ni to both improve performance and reduce corrosion.

For more information, visit xtalic.com/nanocrystalline-ni-cr.

Contents

About Xtalic Corporation

Founded by the Department Head of Material Science and Engineering at the Massachusetts Institute of Technology, Xtalic Corporation designs and develops unique high-performance metal alloys with tailored, thermodynamically stable nanostructures. Xtalic alloy coatings have advanced wear, corrosion resistance, strength, temperature tolerance, and other key performance measures. For more information, visit www.xtalic.com.

# # #

Media Contact:

Robert Legg, Director of Product Management and Marketing,

+1-508-485-9730, Rlegg@xtalic.com