Our Technology

Advanced material technology has become critical as our world electrifies, miniaturizes and builds more devices. Using our computational materials design platform we can design out poor performing metals by tailoring sustainable high-performance nanostructured metal alloys. These key building blocks for your everyday products unlock the technology behind the next generation of product features that society covets the most.

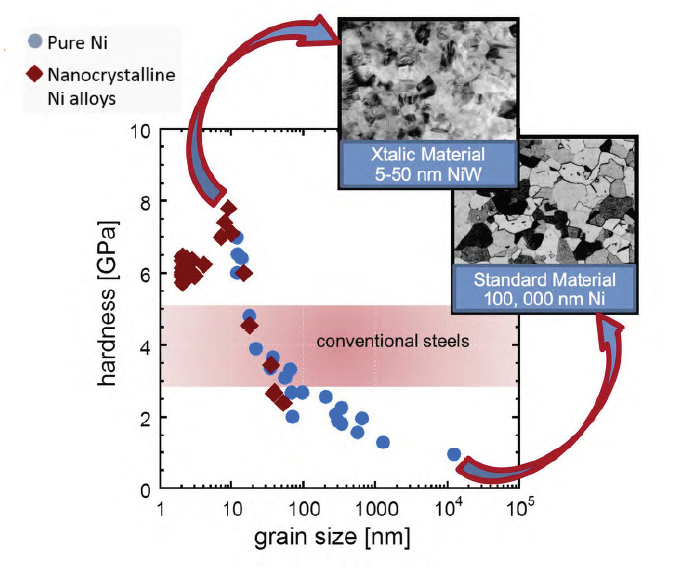

Metal is commonly used for its structural, electrical, or aesthetic properties. There are many methods to manufacture and enhance the properties of metal. Reducing grain sizes is a well known method used to increase the performance of metal.

By engineering grain sizes you can tailor the functional, electrical, mechanical and magnetic properties of metal.

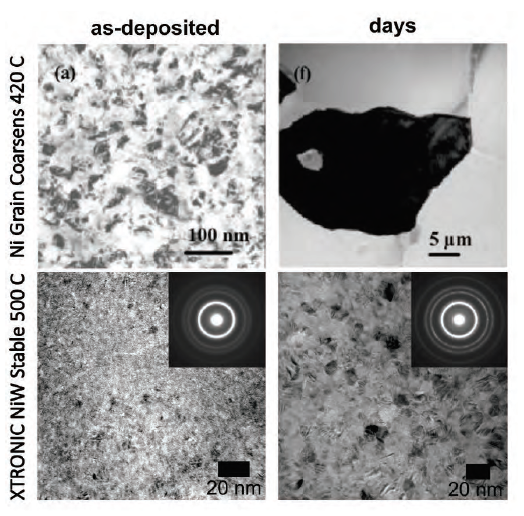

Traditional manufacturing methods create unstable nanostructured metal alloys that lose their key properties over time and temperature. However, technology breakthroughs at MIT identified methods to engineer alloys that create stable nanostructured metals enabling their use across multiple real world applications.

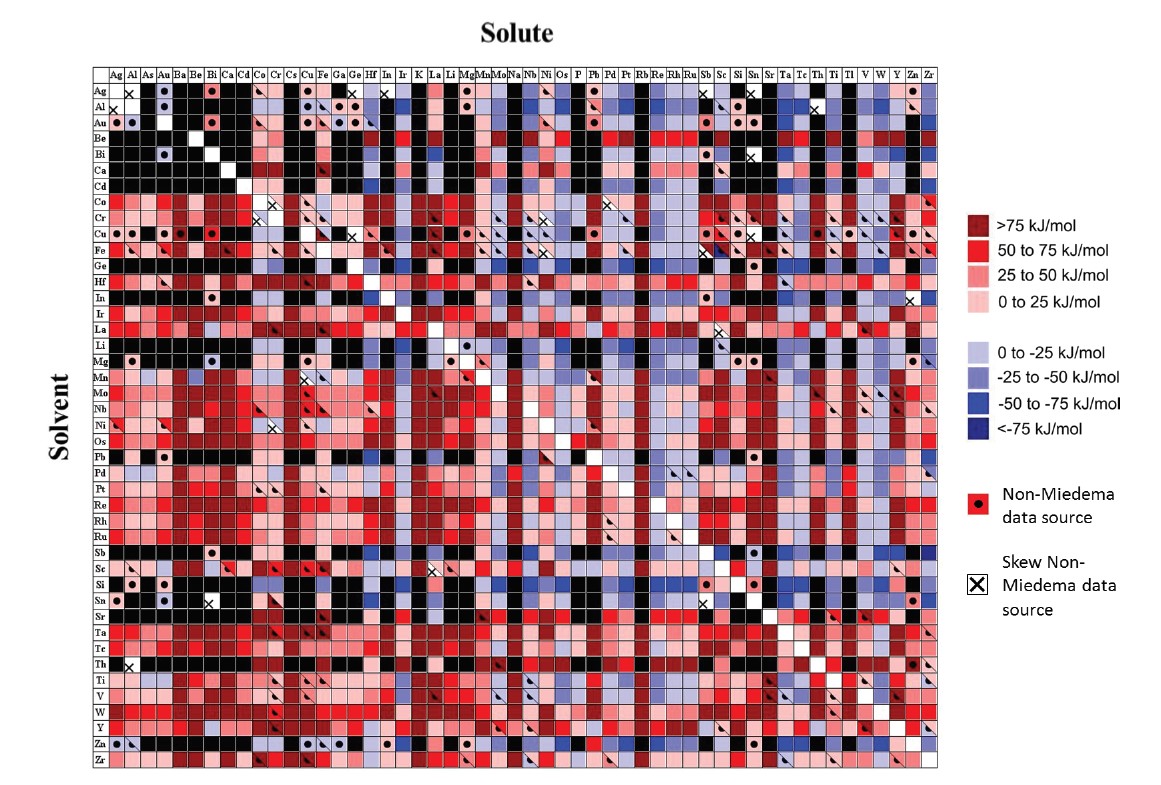

Xtalic originally used algorithms that identify stable binary nanostructured metal alloys to move quickly from discussing customer needs to identifying potential solutions.

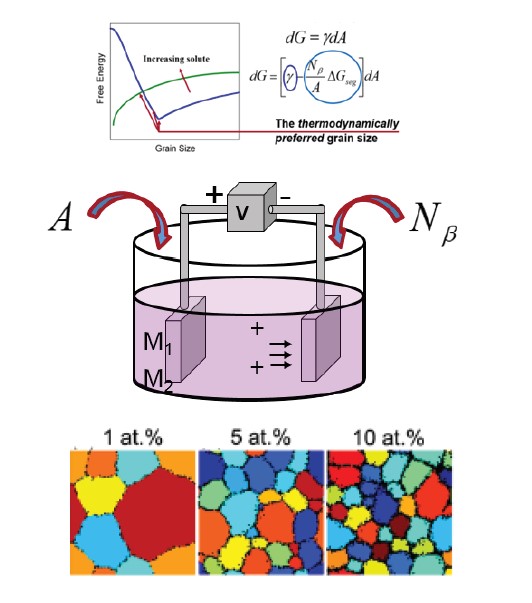

Today we are expanding our computational material design platform to include ternary and higher order alloys, better identify broader performance impacts and gain more granularity in controlling these properties with MIT and industry partners.

Xtalic controls the alloy by engineering the way atoms work with each other to form a specific nanostructure using proprietary pulse reverse electrodeposition wave forms and custom chemistry. Alloying elements are chosen through our computational material design platform to ensure a thermodynamically stable nanocrystalline structure. Dynamic Nanostructure Control® enables us to control the concentration of these alloying metals, thus the grain size and properties of the metal, ensuring outstanding product performance.

Our computational materials design platform continues to evolve through industry engagement and a strong relationship with MIT.

Our Alloys

XTRONIC® is the first commercialized stable nanostructured metal alloy. It has saved 60% of all your high speed internet connections $178m in gold, 78mKg of CO2 since Amphenol began using it for switch and router connectors in 2010 and protects more than 2 billion smartphone charging connectors in your pockets today.

LUNA® is one of the world’s hardest high temperature silvers in the world. It can operate above 210 C. The hardness and electrical properties are similar to hard gold but at 2% of the mining impact of gold. Today it is used to create safer wearables and enable the next generation of reliable electric vehicles.

XTALIUM® is a suite of nanostructured aluminum alloys electroplated from ionic liquids. It has enabled one of the lightest materials in the world, has the strength of steel and can be anodized for a full palette of colors.

XTALIC is actively exploring new nanostructured copper, platinum, palladium, and iron alloys. Talk to our technical experts to discuss a solution to your applications.