— Enables Increased Power Transmission and Thermal Stability at Higher Temperatures in High-Power Connectors and Charger Contacts —

MARLBOROUGH, MASSACHUSETTS, USA — May 18, 2021 — Xtalic Corporation today announced that its patented LUNA® nanostructured silver coating delivers substantial performance benefits for critical high-voltage Electric Vehicle (EV) electrical connections — high-power connectors and charger contacts — including boosting connector drivetrain performance, extending safe temperature ranges in power electronics, and reducing charging times.

For EV manufacturers, LUNA represents a significant advancement towards achieving greater ampacity at higher temperatures — enabling increased transient power transmission and extending thermal stability above 220 C — while ensuring reliability, safety, and performance.

In the case of traditional contact finishes such as silver, electrical derating of connectors at temperature provides a safety margin but limits performance. LUNA’s patented nanostructured silver alloy is engineered for elevated temperature contact physics to overcome fundamental limitations of traditional silver — which cannot provide the hardness, strength, corrosion resistance, and durability demanded in the designs of tomorrow’s EVs.

Utilizing the company’s Dynamic Nanostructure Control® and patented Rapid Alloy Design toolkits, Xtalic engineers work with EV OEM and Tier 1 designers to tailor LUNA properties to meet the unique challenges and goals of each critical electrical connection application.

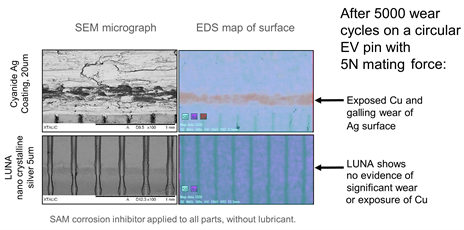

In high-power EV connectors, LUNA targets the transfer of more current at a higher maximum operating temperature (220 C) — while maintaining safe operation. In EV charger contacts, LUNA features a low insertion force and improved wear enabling a much thinner coating (at 25% thickness compared to traditional silver) for better durability and improved corrosion resistance.

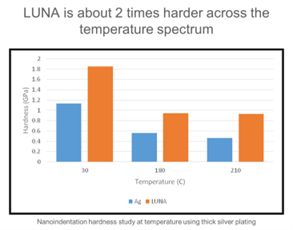

LUNA extends the thermal stability performance of contact physics beyond the maximum contact interface temperature (170 C) and transient current carrying capability limitations of traditional silver. LUNA’s thermal stability provides low and stable resistance after 210 C heat age for 4,000 hours. Also, LUNA is about two times harder than traditional silver plating across the temperature spectrum (23 to 200 C).

The utilization of LUNA in high-power connectors enables increased power at temperature versus traditional silver-plated connectors and the process of implementation is simple. LUNA is manufactured through a traditional electrodeposition process for connectors. Xtalic provides the chemistry, process, and IP access enabling the use of existing electroplating facilities. Xtalic performs material design, early-stage samples, and production support with a global team of application engineers deployed across existing high-volume lines and new supply chain installations.

For more information, visit the Xtalic website at https://bit.ly/3eS5NoU.

About Xtalic Corporation

Xtalic Corporation designs and develops unique high-performance metal alloys with tailored, thermodynamically stable nanostructures. Xtalic alloy coatings have advanced wear, corrosion resistance, strength, temperature tolerance, and other key performance measures. The company’s chemistries are globally deployed across more than 40 high volume manufacturing lines, protecting more than 25 billion critical contacts, including the products of five of the world’s top 10 smartphone OEMs and 30 leading electronics OEMs.

For more information, visit our website

# # #

Note to Editors:

- Media Contact: Robert Legg, Director of Product Management and Marketing,

+1-508-485-9730, Rlegg@xtalic.com - High-resolution images for publication are available on request.