The evolution of electric vehicle technology continues to be shaped by consumer demands for sustainable transportation. As the market determines what applications are most addressable to fill EV technology adoption, battery power output is a concern that can be analyzed by the following aspects: fast charging, battery swap, and wireless charging.

Contents

Fast Charging Electric Vehicle Technology and Its Challenges

Fast charge is a pivotal feature for EV manufacturers as automakers aim for 80% charge in 20 minutes. Technologies like liquid cooling, advanced surface coatings on the charger, and battery management systems all contribute to getting more electrons into batteries safely. The infrastructure for fast charging is growing as more power stations come online to fuel consumers’ needs. These power sources will push energy into batteries as fast as the physics of batteries will allow.

While innovations in fast-charging electric vehicle technology continue to evolve, consumer expectations for vehicle recharge time remain a challenge. Is a 20-minute recharge time acceptable for a consumer who is used to being able to refuel in 3 to 4 minutes with an internal combustion vehicle? Although most applications of electric cars are well suited to an overnight charge to meet the demand, range anxiety continues to limit the adoption of EVs.

Revival of Battery Swap Technology

One way to encourage the adoption of electric vehicles is by the practice of battery swaps. Tesla made a splash with their strategy for battery swap ten years ago, but has since abandoned the approach in favor of fast charge. Technology startup Ample has now partnered with Stellantis to deploy battery swap technology across a greater portion of EV’s on the road. Ample claims a battery swap time of 5 – 6 minutes and leverages a modular battery cell concept to increase flexibility in the swap process. Automaker Nio has partnered with Changan in China to implement 2,000 battery swap stations across China.

Challenges and Opportunities in Battery Swap Technology

Battery swap technology will introduce a new technological requirement for the battery power interface connector. Unlike connectors in fixed battery systems, which typically experience only a limited number of mating cycles, those in swappable battery systems may undergo thousands of cycles both on the vehicle and the battery itself. This heightened demand for cyclic usage may call for advancements in connector technology to ensure the charging interface remains steadfast, secure, and resilient.

The success of battery swaps extends beyond the automotive realm, finding popularity in the e-bike market. Here, standardized battery packs facilitate swift replacements, enabling electrified motorcycles to promptly return to the road. This approach resolves the inherent engineering challenges posed by the need for an instantly available charge while concurrently adhering to the preference for slow charging to preserve battery cycle life.

A Growing Trend for Wireless Charging Electric Vehicles

Finally, wireless charging for electric vehicles is gaining traction. Users are drawn to the concept of easy and contactless charging, whether in public or private settings. Companies such as Witricity and Plugless Power have been actively promoting the power levels, Level 2 charging speeds, and efficiency of wireless charging systems.

Dynamic wireless charging has the potential to revolutionize the electric vehicle technology landscape of battery capacity and on-the-go charging while driving. Stellantis and Electreon are collaborating on US-based embedded dynamic charging demonstrations in mile-long segments. However, the infrastructure costs for implementing this type of wireless charging may be budget-prohibitive without additional technological innovations aimed at reducing costs.

The Role of Advanced Materials in Electric Vehicle Technology

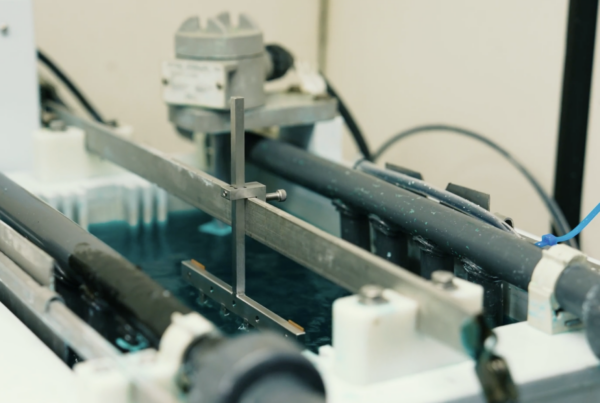

In the realm of electric vehicle technology, Xtalic Corporation stands at the forefront of innovation, providing cutting-edge solutions to address the evolving needs of EV manufacturers. One of Xtalic’s standout technologies is LUNA®, a patented nanostructured silver coating designed to increase transient power transmission, extending thermal stability up to 220°C while ensuring reliability, safety, and overall performance.

Mechanically, LUNA® exhibits remarkable hardness, surpassing traditional silver across temperature spectra. As electric vehicle technology becomes integral to our transportation ecosystem, Xtalic will continue to play a crucial role in shaping the future of high-voltage automotive interconnects, providing solutions that amplify durability, wear resistance and overall efficiency.