We are proud to announce the opening of Xtalic’s new technical center in Shenzhen, China. This expansion reinforces our commitment to accelerating materials innovation and supporting customers worldwide.

The 7,000-square-foot facility brings together a showpiece reel-to-reel plating line, R&D, testing, analytical capabilities, and sample production under one roof. By placing these capabilities closer to our Asia-based customers, Xtalic is significantly improving the speed, efficiency, and collaboration required to design and scale next-generation alloy solutions.

Xtalic’s headquarters in Marlborough, Massachusetts will continue to serve as the main hub for customer collaborations and new alloy development. With increasing demand for high-performance, durable, and cost-efficient materials, the technical center enables the hands-on engineering needed to support customer programs in Asia.

Shenzhen is home to many of Xtalic’s OEM customers and key supply chain partners across consumer electronics, wearable technologies, semiconductor hardware, and data and power interconnects. By expanding our technical presence in China, Xtalic can work in real time with leading manufacturers and accelerate bringing innovations to market, with higher reliability and lower cost.

Contents

A Center for Engineering Excellence

The technical center is designed to serve as a full-service hub for alloy sampling, testing, and production. The facility includes:

- Electroplating development labs capable of testing new alloy chemistries.

- Analytical wet chemistry and materials characterization capabilities.

- Pilot plating lines for process development and customer sampling.

- On-site technical support teams to assist customers directly with troubleshooting, optimization, and design.

Coupled with existing capabilities at Xtalic’s Marlborough headquarters, the technical center creates an integrated workflow that shortens the path from concept to commercialization, reduces development cycles, and enables customers to evaluate new coatings and finishes with greater precision.

Advancing Xtalic’s Mission Through Global Innovation

For over 20 years, Xtalic’s headquarters in Marlborough, Massachusetts has supported customers with new alloy development to replace poorly performing materials and overcome product roadblocks. Our Marlborough office will continue to serve customers with:

- Product roadmapping support

- Computational materials design development

- Electrochemistry and process development

- Rack, barrel and reel-to-reel product sampling

- Rapid product level testing

- Scaling to high volume manufacturing

- On-site global production support

For customers across Asia, the technical center represents a major expansion of Xtalic’s ability to provide localized, responsive support. By expanding testing, failure analysis, and sample production closer to manufacturing hubs, Xtalic can:

- Deliver faster response times

- Support evaluation and qualification of new materials

- Provide hands-on engineering guidance

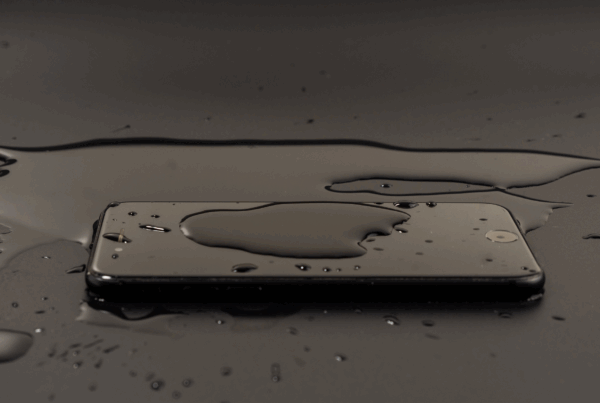

Proximity also enables closer collaboration on product-specific material properties, including waterproofing, corrosion resistance, connector reliability, and precious metal reduction strategies.

As Xtalic enters its third decade, the technical center stands as a symbol of our continued commitment to innovation, partnership, and customer-driven materials engineering.