The TMS 2023 annual meeting is a chance for the deep science of materials innovation to be communicated and shared through the materials community. This year’s agenda included a whopping 24 sessions dedicated just to nanostructured materials. With 4500 attendees from around the world, there is ample opportunity to learn, invent, network, and share.

There are three branches to TMS: mining, metals, and materials. David Danielson, who leads Breakthrough Energy Ventures, was the keynote speaker this year conference, addressing opportunities to impact climate change with materials design and how that impacts each of the three branches of TMS. BEV invests in technology companies that can significantly impact climate through carbon footprint reduction or elimination. Since materials technologies can take some time to get to market and reach their full potential for commercialization, the time to start building new materials is right now.

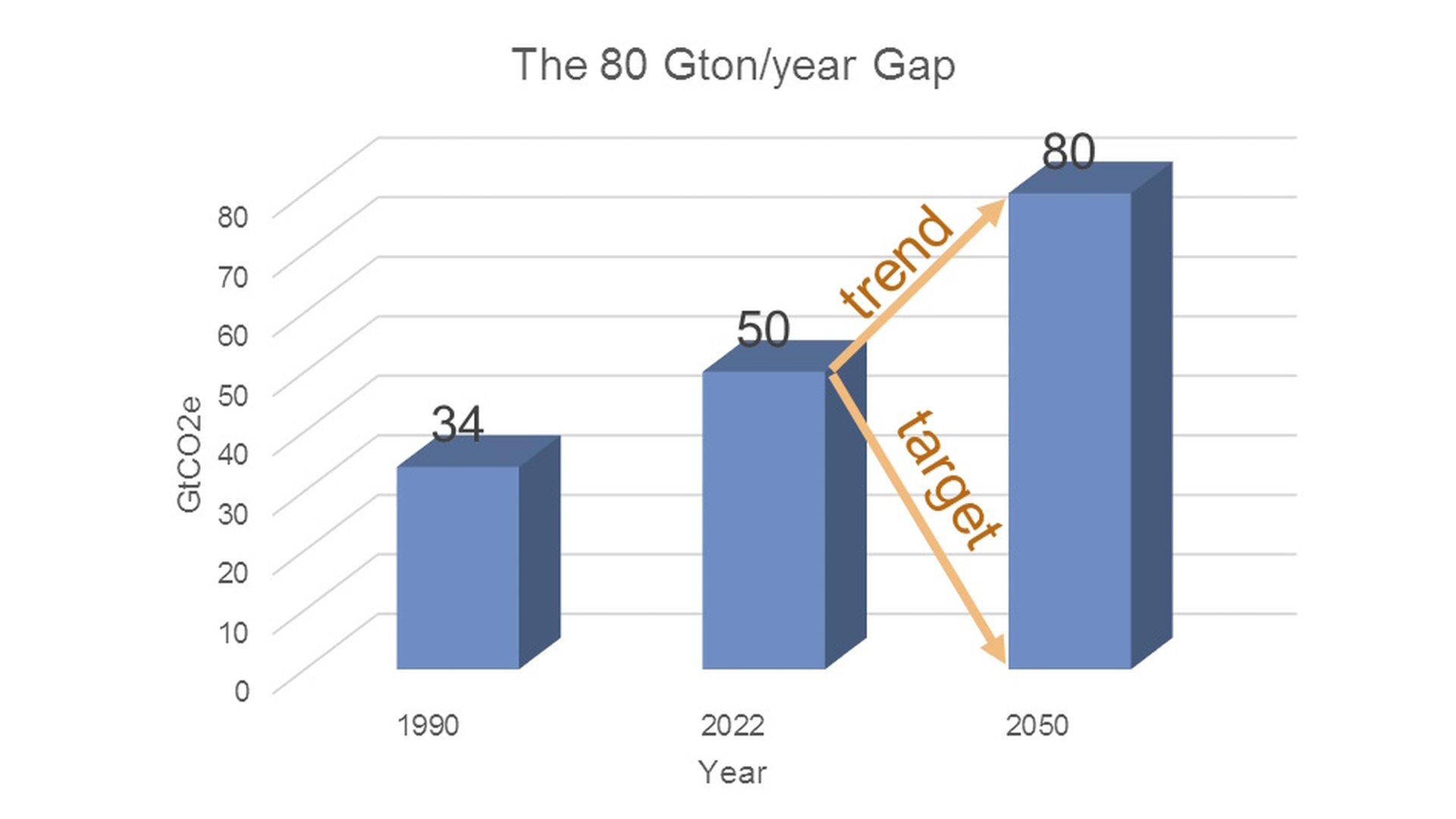

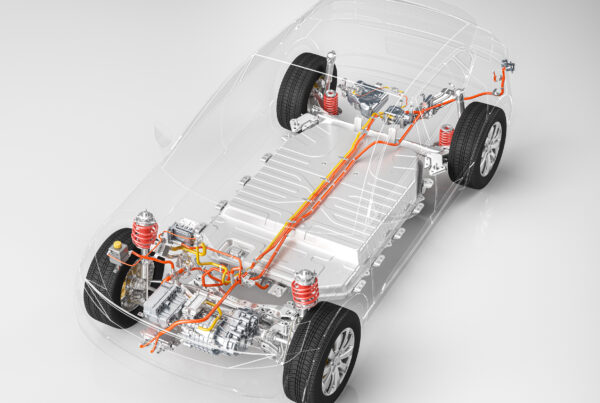

On our current trajectory, we need to create carbon-reducing technologies at the scale of 80 gigatons per year to have a shot at being carbon neutral. Seemingly pedestrian technologies, like mining iron ore for steel, are significant greenhouse gas producers. Developing new extraction technologies and even the development of improved electric vehicles for mining equipment can have a huge impact on reaching our carbon goals.

I met with the Director of Materials Development for a major consumer electronics brand at the conference. They expressed the need for more materials technologies to help with carbon footprint and highlighted some of the headway their company has made towards being carbon neutral. One example is the use of certified recycled gold on the motherboards of their flagship products. Recycled gold requires just 0.2% of the energy required to mine and extract new gold from the earth.

While global supplies of recycled gold remain low, there is an opportunity to reduce environmental impact and collaborate with the leaders in environmental best practices. Universities are doing some advanced fundamental work toward understanding nanostructured metals design and performance. Andrea Hodge at USC gave an update on her team’s work on nanolayered composites made by PVD. The Mo-Au system has shown to be thermodynamically stable to 400 C. Following on the work of Jason Trelewicz at Stony Brook, they showed how atoms that segregate to the grain boundaries can, in some cases, collect there and lead to grain boundary thickening. In this case, we are adding extra atoms to the grain boundary and no longer using those atoms to aid in grain size reduction, but they may aid in reducing grain boundary diffusion.

Gianna Valentino from the University of Maryland updated us on her research into ternary Ni-Mo-W alloys. Ni-W is the basis of Xtalic’s XT product, and we have also published about the segregation behavior of Ni-Mo. However, when these are combined as a ternary alloy, we see that the metallurgy changes some as the stacking fault energy is reduced and nanotwins are formed. This is another route to strengthening in a nanostructured metal material. Gianna’s fundamental work here helps us understand the relationships between stacking fault energy and the enthalpy of segregation in how it relates to nanostructured alloy design.

In the end, we need materials to perform and help us solve problems. Researchers provided evidence of materials that can perform like never before, batteries that charge quicker, surfaces that wear slower, and materials with record-setting strengths. It is up to us as engineers to combine these technologies to build products for a better tomorrow.