XTALIUM®

XTALIUM® is a breakthrough in electroplated aluminum technology, delivering unmatched strength, corrosion resistance, and lightweight efficiency. Engineered with a unique nanostructure, XTALIUM combines the strength of steel with the lightweight benefits of aluminum. The supersaturated solid solution nature of the alloys boost corrosion and eliminate stress corrosion cracking. Developed with Xtalic’s proprietary materials design platform, XTALIUM is transforming key industries by improving product performance and reducing environmental impact.

Downloads

Superior Strength – Matches the strength of steel while remaining lightweight.

Exceptional Corrosion Resistance – Protects aluminum, magnesium, and other substrates from degradation in harsh environments.

Scalable Thickness – Ranges from 50 nanometers to 1 millimeter for various applications.

Thermal Stability – Thermodynamically engineered to withstand temperatures up to 300°C.

Electrically Conductive – Approximately 10% IACS for electrical application needs.

Three versions of XTALIUM nanostructured aluminum alloys configured for various mechanical property profiles, each with strengths far exceeding those available from traditional aluminum alloys.

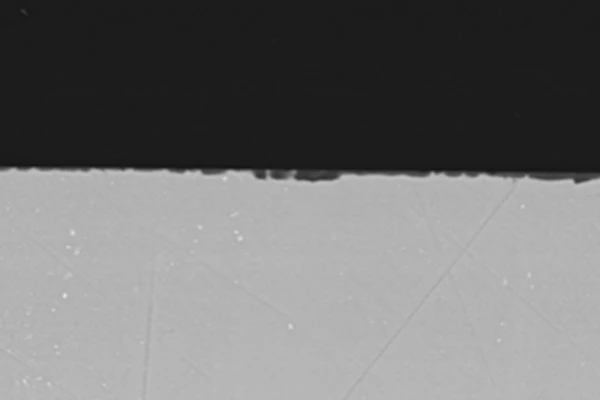

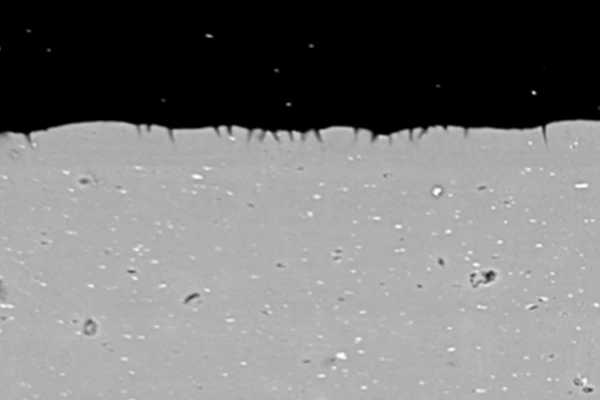

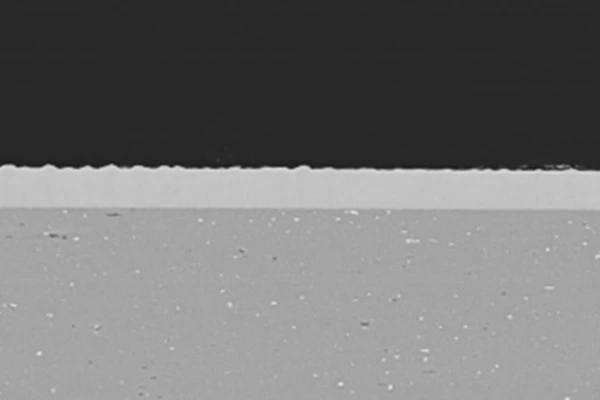

After 3000 hours of ASTM B117 salt spray testing, XTALIUM shows no evidence of corrosion, outperforming both bulk UNS A96061 aluminum (which shows shallow broad pitting) and pure aluminum (which shows deep vertical pitting up to 10 μm).

Xtalium nanostructured aluminum alloy protects the surface of these high performance military helicopter fasteners. The unique structure of XTALIUM provides excellent adhesion and outstanding salt spray corrosion performance.

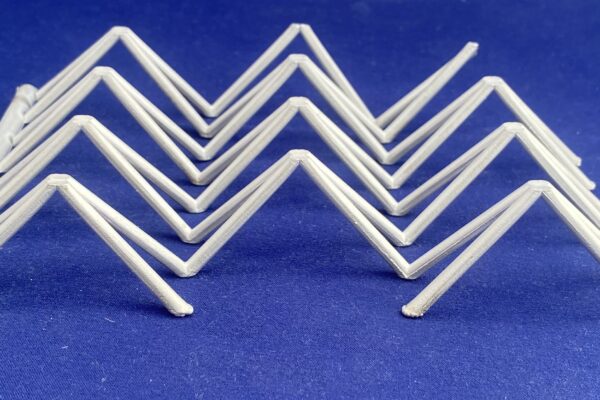

Xtalic partnered with Hughes Research Labs to develop ultralight engineered trusses. These lightweight structures utilize XTALIUM as a super strong and lightweight electroformed layer on top of a plastic skeleton structure. The plastic substructure can remain as part of the part or for ultra-lightweighting, the polymer can be leached out after plating to produce strong engineered hollow tubes of nanostructured aluminum alloy.

Lightweighting for Performance – Reduces overall component weight, improving feel in consumer applications and boosting fuel efficiency in automotive and aerospace applications.

Enhanced Durability and Corrosion Protection – Provides a tough protective layer on top of susceptible alloys, like magnesium and low grade aluminum, extending product lifespan.

Versatile Manufacturing Capabilities – Can be applied as a coating or electroformed into complex shapes for structural applications.

Sustainable & Cost-Effective – Enables the use of light weight but corrosion-prone materials by engineering the surface to enhance their performance.

Transform Your Products With XTALIUM

XTALIUM is produced using pulse reverse electrodeposition in an ionic liquid environment. This advanced manufacturing process ensures stronger, more reliable components that outperform conventional aluminum alloys while maintaining lightweight efficiency.

Precise Grain Structure Control

Achieves nanostructured coatings with superior mechanical properties.

Soluble Anode Technology

Maintains alloy consistency for high-performance applications.

Versatile Application Methods

Supports barrel and rack plating for scalable production.

Safe Operating Conditions

Operates at bath temperatures below 60°C and without harmful or dangerous solvents.

Automotive

Improves fuel efficiency and structural integrity in lightweight vehicle components.

Aerospace

Reduces weight in critical structural parts while maintaining strength.

Consumer Electronics

Enables durable, corrosion resistant and lightweight designs for mobile phones and wearables.

Industrial Applications

Protects corrosion-prone metals in harsh environments.

Lower Carbon Footprint

Aluminum has a relatively small carbon footprint of just 8 kg CO2/kg Al produced.

Improved Recyclability

Aluminum-based alloys that can be easily reclaimed and repurposed.

Reduced Material Waste

Allows for thinner, stronger coatings, reducing overall material consumption.

Materials Efficiency

Enables manufacturers to use lighter, more sustainable materials while maintaining performance.

Contact Us

Connect with our engineers to learn more about how XTALIUM can enhance your manufacturing process, reduce weight, and improve durability.

"*" indicates required fields