Metallurgical wear is one of the leading causes of failure in engineering components, rivaling corrosion in both cost and impact. Metallurgists leverage known strategies to reduce wear on components by increasing hardness or introducing lubricants. Xtalic is advancing a complementary approach: engineering alloys that form protective tribofilms during operation.

Contents

What Are Triboflims?

Tribofilms are diamond-like materials that form on the surface of certain metals and significantly reduce wear rate. Most commonly, these films form spontaneously and catalytically on precious metal surfaces like platinum, iridium and palladium(2). Further, these tribofilms can be self-healing if the hydrocarbon source remains present on the surface.

Xtalic has developed a patented, precious-metal-free, Ni-Mo-Cr alloy that delivers outstanding wear performance and thermal stability while enabling tribofilm formation. (1, 3)

Applications

Tribofilm formation requires at least one exposure to hydrocarbons. As a result, ideal applications include:

- Fuel pumps

- Lubricated wear and clutch plates

- Bearing surfaces

- Gears and transmissions

- MEMS components

Alloy Design Approach

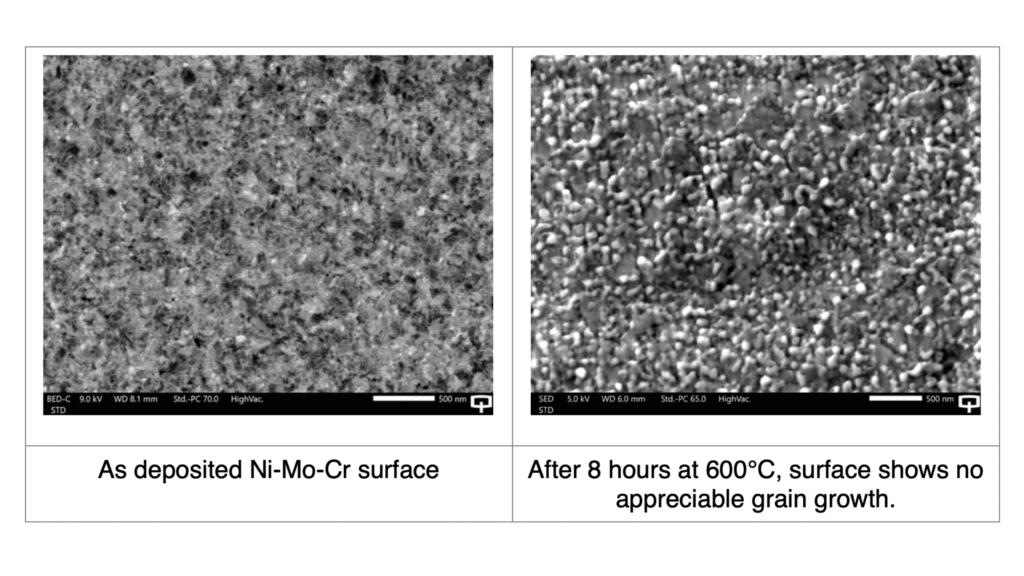

Using the Xtalic Computational Toolkit, we engineered a nickel-based alloy capable of forming durable tribofilms without relying on precious metals. To enhance hardness and wear resistance, the alloy incorporates molybdenum in a nanostructured nickel matrix. Molybdenum preferentially segregates to grain boundaries, creating a thermodynamically stable structure that resists wear.

To further boost wear resistance, we introduce chromium to the alloy. Both chromium and chrome oxide act as catalysts in the presence of hydrocarbons and lead to the formation of diamond-like carbon tribofilms. Chromium oxide further reduces the corrosion rate on the surface.

Tribofilm Formation and Performance

Tribofilms form on the Ni-Mo-Cr alloy surface when exposed to hydrocarbons. In experimental testing, U.S. Army Jet Fuel 24, a synthesized hydrocarbon mixture with paraffins and stabilizing additives (C9–C16), was used to initiate tribofilm formation. Tribology tests performed on the alloy after a liquid layer of jet fuel was applied led to the creation of the tribofilm and substantially reduced wear rates.

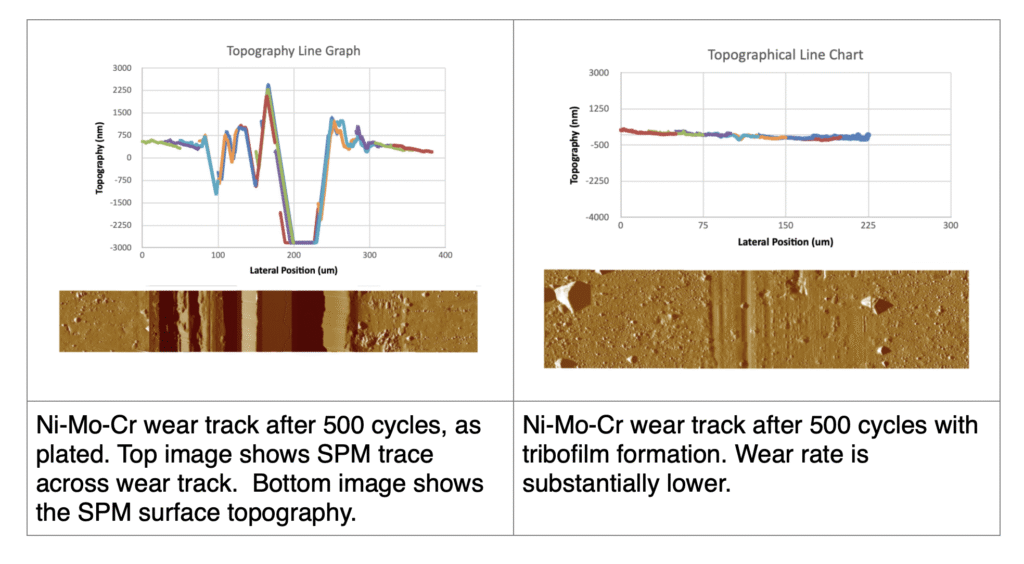

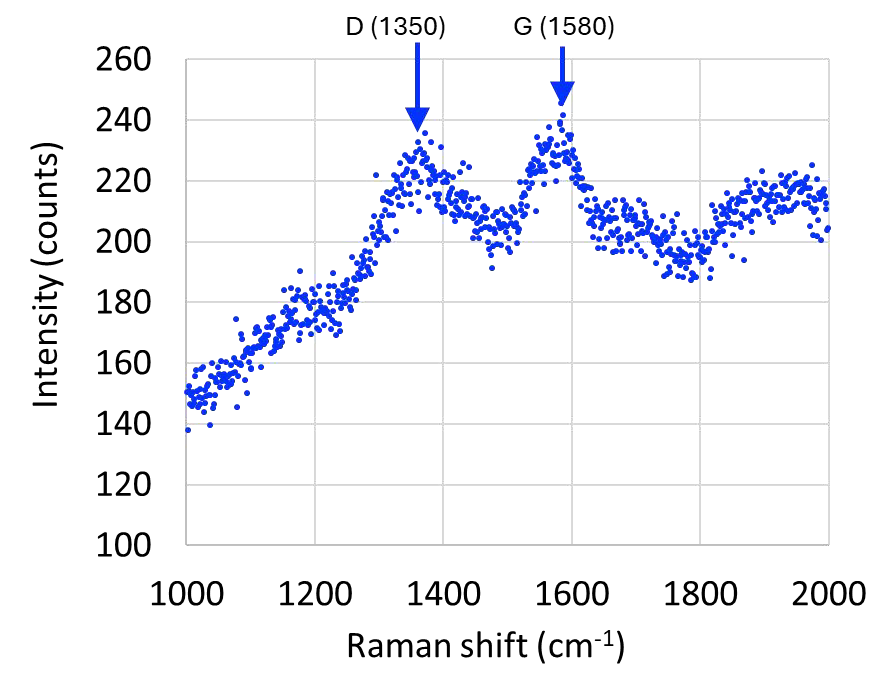

Figure 1 shows the Raman spectroscopy of the tribofilm indicating the presence of the DLC carbon bands within the wear track. Figure 2 shows the scanning probe microscopy surfaces of the Ni-Mo-Cr alloy tested with and without the tribofilm (1um Ni-Mo-Cr on 52100 steel, 1.5GPa Hertz stress, reciprocating wear, mated to 52100 steel). When the tribofilm is present the wear rate drops substantially.

Figure 1. Raman spectroscopy in the wear track showing the presence of D and G carbon bands. (Data courtesy of Northwestern University)

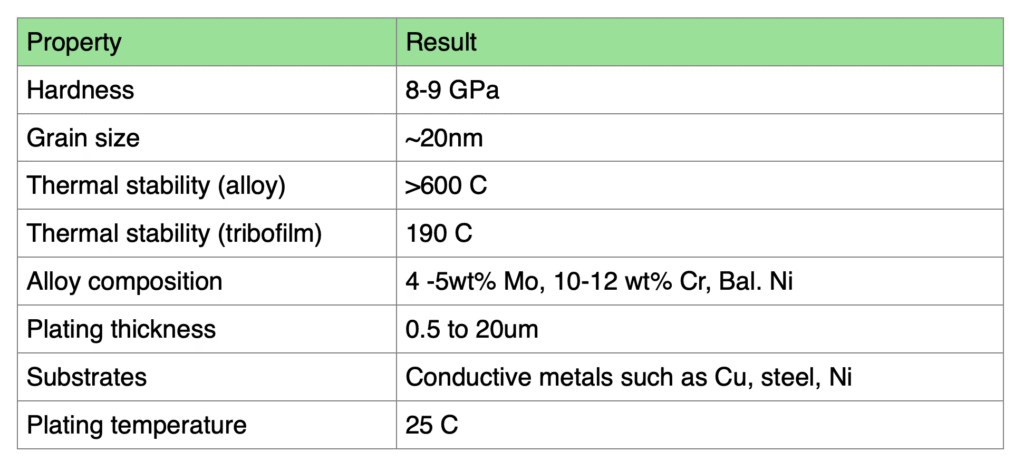

Properties

Technology Readiness

The plating process and chemistry has been developed to a prototyping readiness level. Rack plating is being used to sample prototype parts from our laboratories and technology center in Marlborough, MA. Barrel plating and reel-to-reel plating processes are under development.

References

- Part of the evaluation and characterization of these materials was performed in collaboration with Questek and Northwestern University under funding from the US Army.

- “Achieving Ultralow Wear with Stable Nanocrystalline Metals”, Curry et al, Adv Mater. 2018 Aug;30(32):e1802026. doi: 10.1002/adma.201802026.

- Hilty, Freydina, Abbott, US Patent 11247434 B2, 15FEB2022.