XTRONIC®

XTRONIC® is the first nanostructured nickel tungsten alloy commercialized at scale to meet the demands of high-speed connectors and power applications. Developed using Xtalic’s proprietary computational alloy design platform, XTRONIC sets a new benchmark in connector finish performance by engineering grain structures at the nanometer level. Designed to reduce reliance on costly precious metals like gold, XTRONIC delivers exceptional durability, corrosion resistance, and cost savings. XTRONIC is the smarter, sustainable choice to future-proof a variety of applications from high-speed data connectors to consumer electronics and more.

Downloads

Nanostructured nickel tungsten composition for engineered grain stability

Hardness of 680 HV for high wear resistance

Low and stable contact resistance (<10 mΩ) over time

Superior corrosion resistance, including powered immersion environments

Compatible with high-speed reel-to-reel, rack, and barrel plating lines

Wide operating temperature tolerance — up to 700°C

Conductivity 10-15 W/(mK)

Proven Performance and Cost Savings Across Critical Applications

XTRONIC, nanostructured nickel tungsten alloy, isn’t just a barrier layer, it’s a competitive advantage, enabling manufacturers to optimize costs, improve reliability, and deliver next-generation performance across high-speed data and power applications. Deployed in over 200 billion critical contacts, XTRONIC is trusted by 7 of the top smartphone OEMs for applications where reliability is non-negotiable.

In smartphones, XTRONIC protects over 3.5 billion connectors, including USB-C interfaces, ensuring stable performance and extended product life even after repeated cycles. For enterprise servers and networking hardware, XTRONIC has enabled over 3.5 metric tons($485 million) in gold savings, reducing gold usage by two-thirds without sacrificing performance. This is made possible by XTRONIC’s superior nickel tungsten barrier properties: when tested against the industry-standard nickel sulfamate, traditional coatings corroded after environmental exposure, while XTRONIC remained intact.

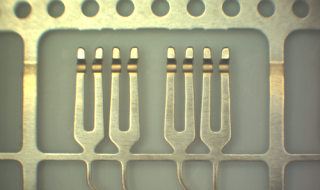

A standard plated part using 3x the required gold that Xtalic connectors use.

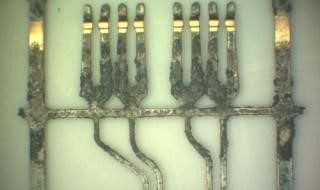

In corrosion testing thick gold protects the contact area but exposed nickel sulfamate is entirely corroded.

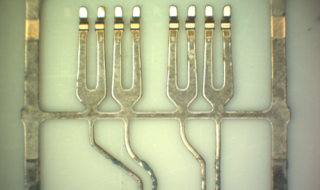

With an XTRONIC barrier layer, gold thickness is reduced by two-thirds and electrical components do not corrode as compared to conventional nickel sulfamate.

Up to 5x improved wear durability compared to traditional coatings

Up to 67% reduction in gold usage, with direct COGS savings

Order of magnitude enhancement in immersion corrosion performance for waterproof designs

Over 80 million kg of CO₂ savings from reduced gold mining, to date.

Drop-in compatibility with existing manufacturing infrastructure

Proven scalability, with tens of billions of units deployed globally

Transform Your Products With XTRONIC

Based on your application and specific product needs, Xtalic can customize the material properties of XTRONIC to help you find the right formulation.

XTRONIC PM: Optimized for gold reduction

XTRONIC BL: Enhanced waterproofing performance

XTRONIC GR: Tailored for barrel plating applications

XTRONIC is produced using Xtalic’s advanced pulse reverse electroplating technology, ensuring uniform nanostructures and consistent performance. The alloy is suitable for plating thicknesses from 0.1 to 20 microns and can be applied using:

- High-speed reel-to-reel plating

- Rack and barrel plating

- Cyanide-free chemistries

- High-speed data connectors (server, router backplanes)

- Consumer electronics (ie. I/O and USB-C charging ports)

- Automotive infotainment and electronics

- Pogo pin style interconnects

- Telecommunications infrastructure

- Over 3.5 metric tons of gold saved across deployments, which amounts to over $380 million globally

- Significant CO₂ reductions linked to gold mining avoidance

- Tungsten sourced from ethical and recycled supply chains

- Supports ESG goals while lowering total cost of ownership

Contact Us

Connect with our engineers to learn more about XTRONIC.

"*" indicates required fields