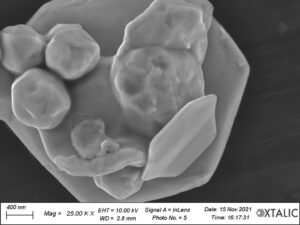

Over 15 years ago, novel computational material design tools were developed at MIT with a specific focus on the role of nanostructure (i.e., grain boundaries) on alloy stability. So what is that state-of-the-art material design team working on now?

Today the team at the Massachusetts Institute of Technology (MIT) led by Professor Christopher A. Schuh, Ph.D., Xtalic’s Chief Scientist, continues to create more sophisticated computational tools that focus on finer control over properties while increasing the real-life accuracy of theoretical material design and modeling. Because nanostructured alloys have rich and varied structures, there is considerable headroom for future scientific improvement in modeling their structure and thermodynamics. Prof. Schuh continues fundamental work at MIT, perfecting computational nanostructured alloy design. With funding from the National Science Foundation and the Department of Energy, his latest works aim to resolve alloy thermodynamics with quantum-mechanical accuracy. This would represent an ideal solution to the problem of grain boundary alloying. Still, it is a significant challenge that was not possible before the advent of high-throughput computing and machine learning techniques. The result will be ideal accuracy with minimum uncertainty and an additional improvement in alloy selection cycle times.

A key expected outcome of these new advances is a fully computational method to scan multinary alloy space: combining multiple elements together in a grain boundary can achieve much greater degrees of stability, but the problem has not been tractable due to limitations in the theory. Prof. Schuh’s current works address this problem rigorously for the first time, and the expanded range of possible alloys increases dramatically as a result. While there are hundreds of binary metal bases, there are more than 2,500 ternary bases and tens of thousands of multinary ones. In this vast search space, there is reason to expect new alloys with far greater stability and properties beyond anything yet attained in our successfully commercialized alloys. In the coming years, these advanced models are also projected to provide a priori input about the temperatures over which stability can be achieved for a given alloy, allowing another phase of experimental work (stability testing) to be moved into the computer and streamlining the alloy development process.

While MIT Prof. Schuh continues to develop computational material design tools at the forefront, Xtalic works closely with industry leaders to leverage scientific breakthroughs into real-life commercial applications. Xtalic is already beginning to take advantage of the new theoretical developments for ternary and multinary alloy design from Prof. Schuh’s group.

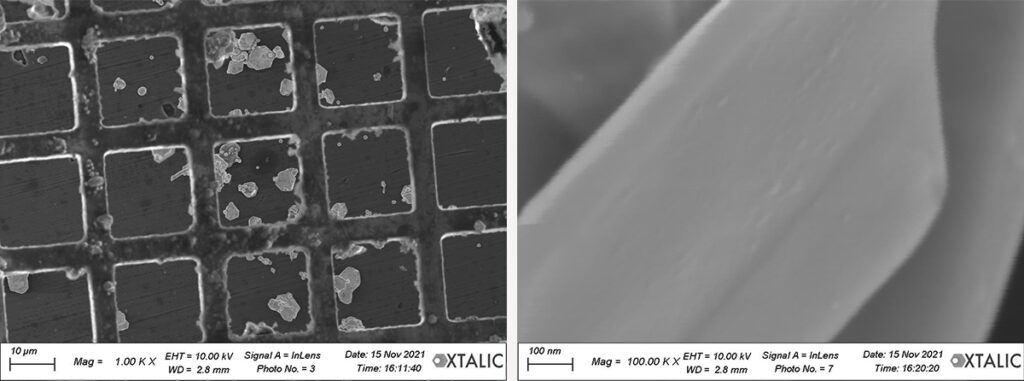

In fact, Xtalic’s most recent corrosion-resistant alloys are already based on modern grain boundary alloying models that incorporate atomic-level details of the grain boundary structure, as well as machine-learning methods that can rapidly scan the entire periodic table to identify preferred alloying elements for the grain boundaries. These advanced design tools shorten the cycle time for new metal alloy design and development: modeling delivers a tighter down-selection of preferred alloys for detailed laboratory investigation, often leading to a successful alloy design in just a few experimental iterations. The most recent high-performance alloys under development at Xtalic were brought through the proof-of-concept stage from a blank slate in as little as three months. The early R&D phase of new materials design is no longer the rate-limiting stage for advanced coatings in these cases.

Xtalic will continue to leverage these findings and work closely with industry leaders to further develop additional design tools, rapid-test methodologies that mimic real-life applications, and eventually, scale computationally designed materials to commercial high-volume applications with mission-critical performance needs. Xtalic continues to invest in tools that enhance rapid test methodologies and capture new levels of product performance as MIT moves beyond atomic-level computational material design. Xtalic computationally designed materials already protect more than 70% of high-speed internet connections and smartphones. These new material designs and test developments can be applied to everything from electric vehicles to wearables, improving the performance, sustainability, and cost of products we will use throughout our everyday lives.

Sign-Up for Behind the Scene Insights With Our Material Design Experts